With the arrival of the peak season for home decoration, the issue of home wiring has become a topic that we must pay attention to. Home decoration wires are directly related to your electrical safety, convenience, and stability for the next few decades. However, there are numerous brands in the market with uneven quality, making it easy for ordinary consumers to fall into misunderstandings. The following guide, combined with industry standards and practical experience, will teach you how to identify and purchase high-quality home decoration wires like a professional electrician:

Step 2: Fire Eye and Golden Eye - Identify High Quality Wires

Please bring this' Quality Inspection Checklist 'with you when making a purchase:

1. Check the brand and certification:

Choose reputable and reputable reputable brands (such as mainstream domestic brands). Brand is the first line of defense for quality assurance.

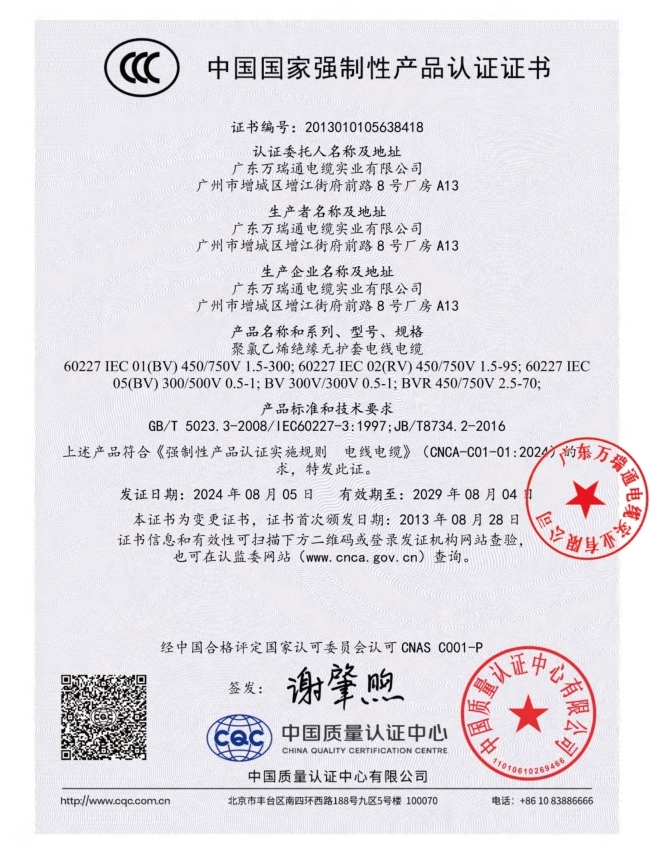

Compulsory certification: It is essential to ensure that the product has the CCC certification (China Compulsory Certification) mark! This is a basic requirement. Please carefully check the certificate number (which can be found on the official website).

Other certifications (bonus points): ISO9001 quality management system certification, national inspection free products (valid year to be checked), flame retardant level identification (such as ZR-BV, it is recommended that home decoration wires reach at least flame retardant level C).

2. Check the outer packaging:

The packaging printing should be clear and complete, including brand, model specifications (such as BV 2.5), CCC mark, factory name and address, implementation standards (GB/T 5023.3-2008, etc.), production date and length (usually 100 meters/roll), and accompanied by a certificate of conformity.

The packaging is intact and there is no serious damage.

3. Check the insulation layer (outer skin):

Material: High quality PVC material, with uniform and bright color and toughness; Poor quality materials may have dull colors, impurities, or turn white.

Thickness: Pinch it with your hand and you should feel that the thickness is uniform and firm; Using a vernier caliper for measurement is more accurate. Being too thin can easily lead to damage and is unsafe.

Resilience: Cut a small section and bend it repeatedly by hand, but do not apply too much force to break it. High quality lines will turn white at bends but are not easily broken, and can rebound to a certain extent; Poor quality lines may break easily or appear stiff and inelastic.

Flame retardancy test: A small corner of the insulation layer can be ignited with a lighter (be careful!). High quality flame-retardant circuits should be able to self extinguish after removing the fire source, while low-quality circuits will continue to burn and drip, which is extremely dangerous! This test should be conducted with caution, preferably referring to the relevant markings on the packaging.

4. Look at the conductor (metal copper core):

Color and Gloss: High quality conductors are made of high-purity oxygen free copper, which is purple red in color and has a soft luster; Poor quality conductors may be composed of recycled copper or impurities, with darker or darker colors and a lack of luster.

Structural uniformity: Excellent conductors have consistent thickness and softness, while poor quality conductors may have uneven thickness and brittle hardness, which may indicate the addition of impurities such as iron and aluminum.

Cross section inspection: (key step)

Cut a small section of the BV line and observe the cross-section. The copper core should be full, round, compact, and free of pores, sand holes, and obvious debris. At the same time, a vernier caliper can be used to measure the diameter to confirm whether it meets the standard square number. For example, a diameter of 2.5mm ² is about 1.78mm. Unscrupulous merchants often reduce costs by stealing area!

BVR lines also need to check whether the thickness and number of copper wires per strand are uniform, while maintaining a bright purple red color. Multi strand designs are more prone to mixing inferior copper wires.

Simple purity testing method:

-Bending method: Take a small section of copper core and bend it repeatedly several times (4-5 times). If it is high-quality copper, it has good toughness and is not easy to break, but the bending point should change significantly; If it is of poor quality copper, it will quickly break and produce a chalky particle like fracture with a strong texture.

-Magnet method: (Important reminder!): Place a strong magnet close to the copper core. If it is high-purity copper, it will not be attracted at all because copper is a non-magnetic metal. If it contains iron element, it will be significantly attracted by magnets, which is an important method for identifying and recycling copper mixed iron!

5. Measuring length:

Legitimate manufacturers generally label 100 meters per roll, but the actual length is allowed to fluctuate within a range of positive and negative errors (usually ± 0.5% according to national standards). However, some vendors also frequently steal rice, so special attention should be paid.

A simple verification method includes checking the meter labels on the outer skin, with corresponding length markings for each meter. In addition, it can also be weighed, but it is relatively troublesome to understand the standard meter weight under this specification.

Wanruitong Cable Engineer reminds you that to scientifically identify qualified home decoration wires, you also need to pay attention to the first and third steps. Please search for relevant information on Baidu by yourself.

+86 136-3137-9141

email:

wanruitong8@gmail.com